Engineering for Extremes: Designing Products That Pass MIL-STD-810 Testing

.jpg?width=800&height=400&name=unnamed%20(1).jpg)

If your product is expected to face heat, shock, vibration, or moisture exposure, it needs to be engineered for survival. In mission-critical environments, rugged performance is what separates dependable solutions from costly failures.

That’s why MIL-STD-810 exists. While often misunderstood as a certification, MIL-STD-810 is a set of environmental test methods developed by the U.S. military to evaluate how products hold up in the real world. It doesn’t dictate how something must be built, but it does challenge you to prove it can survive.

In this blog, we’ll break down the core environmental conditions your product should be designed to withstand, and more importantly, we’ll explore how engineering smarter from the start can make the difference between passing those tests or going back to the drawing board.

The Conditions Your Product Needs to Prepare For

Before you can engineer a product that performs in extreme environments, you need to understand what it’s up against. MIL-STD-810 is a set of standards that engineers design and test for when creating a product. Testing simulates real-world conditions that could impact functionality, safety, or longevity. Depending on your product’s intended use, it may need to pass several of the following:

- High and Low Temperature – Operability in extreme heat or cold, including temperature shock.

- Humidity – Resistance to moisture buildup and internal condensation.

- Sand and Dust – Durability against particulate infiltration in dry, desert-like environments.

- Salt Fog – Corrosion resistance for maritime or coastal applications.

- Shock and Vibration – Structural integrity during transport, impact, or repeated motion.

- Immersion – Submersion in water, often tested at various depths and durations.

- Altitude and Pressure – Performance in low-pressure, high-altitude environments.

- Radio Frequency Interference – Ensures reliable performance near strong radio signals.

- Electro-Magnetic Interference – Confirms the device can operate without causing or being affected by EMI.

Every product has a unique set of challenges based on how and where it’s used. The key is understanding where your product will be used so you can create a product that meets the needs of its use case.

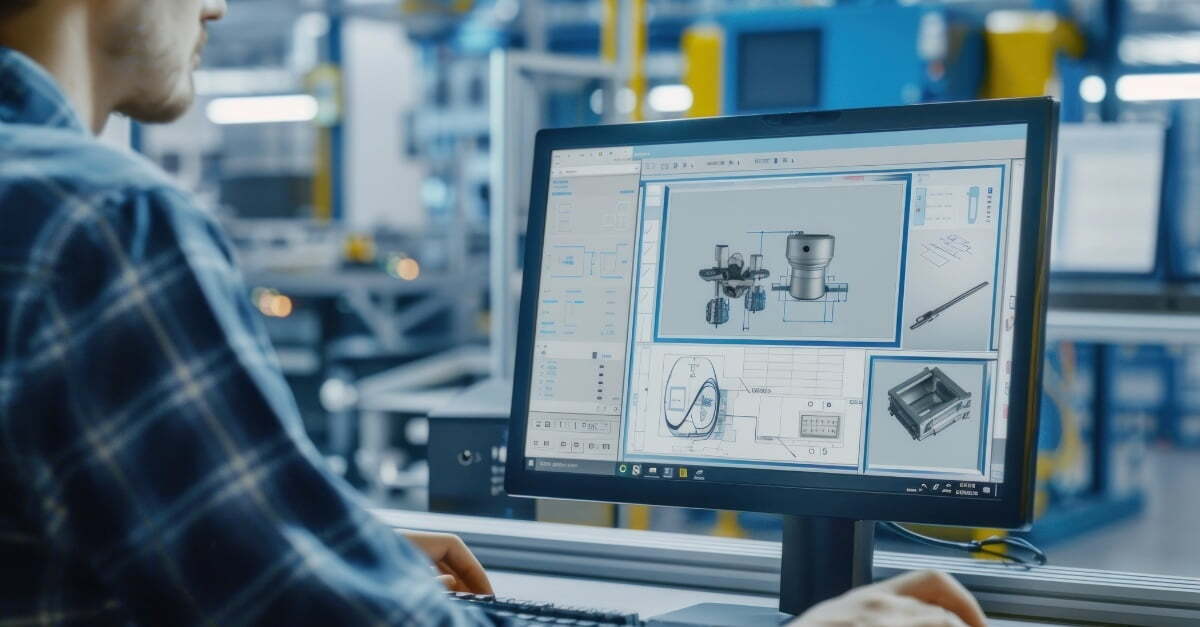

Incorporating Smart Design Choices

The ability of a product to meet MIL-STD-810 standards doesn’t start in testing—it starts at the design table. Early engineering decisions are what ultimately determine whether a product will withstand its environmental exposure once it’s in the field. If the design doesn’t account for environmental stressors from the outset, it typically results in unhappy customers, or worse.

This is where an experienced full-service manufacturer can come in for support. At DEM, our engineering team is involved from day one, helping you identify which MIL-STD-810 methods are relevant to your use case and how to incorporate specific design choices to meet them.

Advanced Prototyping

Once a smart design is in place, the next step is validating it quickly and cost-effectively. The best way to do that is with a representative prototype.

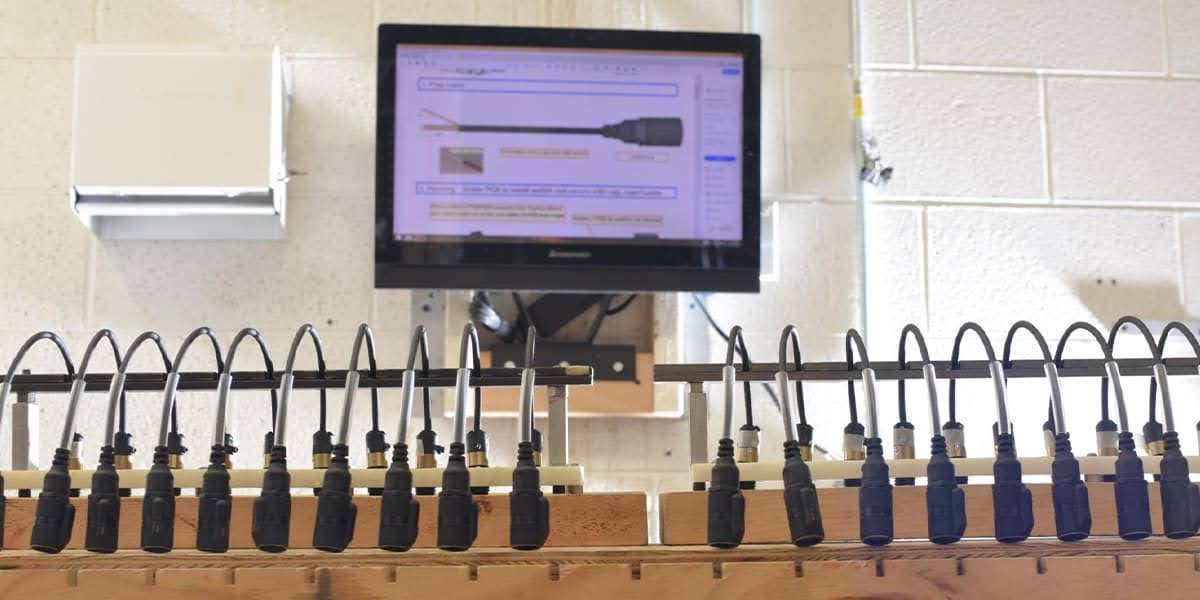

Prototyping utilizing appropriate additive manufacturing techniques and careful selection of materials enables early-stage evaluation of fit and form—confirming component alignment and clearances. This type of prototyping can help identify issues before investing in production tooling.

Testing & Performance Validation

Once you develop first articles, it’s time to test your product against the environmental standards you’re targeting.

That means following the specific test methods outlined in MIL-STD-810 for each applicable condition: whether it’s Method 514.8 for vibration, Method 507.6 for humidity, or Method 516.8 for shock. These tests must simulate the exact scenarios your product will encounter in the field, and the procedures must be applied precisely.

Just as important as the testing itself is how it’s documented. Detailed records of test setups, procedures, and results are essential—not only to validate the product's performance but also to meet the expectations of customers, auditors, and government contractors. Without thorough documentation, even a well-tested product can face pushback or delays in approval.

Need to Build a Product to MIL-STD-810 Spec?

If you're developing a product that needs to withstand the harshest environments, you need a manufacturing partner who understands what’s at stake. At DEM Manufacturing, our cross-functional teams ensure your product is designed, engineered, and manufactured to meet your specific requirements. And because we're 100% U.S.-based and vertically integrated, we can take your product from concept to full production in as little as 10 weeks, without compromising quality or compliance.

Reach out to us today to learn more.

Scott Shemitz

Scott Shemitz is Engineering Manager at DEM Manufacturing, where he leads product design, tooling, and development efforts. Scott’s career spans multiple roles in the automotive and electronics industries, with deep expertise in tooling design and product scalability. At DEM, he supports DFM-focused engineering that bridges concept to production—accelerating delivery without compromising performance.

By

By

.jpg)