Conceptual Design That Lays the Foundation for Smarter, Scalable Products

Every successful product starts with thoughtful, collaborative design. At DEM, we work with you early to define your goals, align on performance, and make smarter decisions so your product development process starts strong.

Where Innovation Meets Practicality

Before any prototypes are built, we help you shape the foundation of your product.

Our conceptual design phase is focused on understanding your vision and exploring the best path forward. Together, we’ll define key requirements and constraints while weighing early choices: functionality, materials, durability, cost, and more.

It’s a collaborative, iterative process designed to keep you in control while reducing surprises down the road

Photorealistic Product Rendering

Know the Cost Before You Commit

Every decision at this stage impacts performance, pricing, and long-term scalability. We make those tradeoffs visible from the start.

Our approach to cost transparency includes:

-

Material selection guidance and sourcing implications

-

Assessment of manufacturing complexity and scalability

-

Design choices that affect tooling, moldability, and production methods

-

Preliminary estimates tied to your desired volumes and pricing goals

We help you avoid costly rework by informing smarter choices early in the product development process.

Throughout the Concept Development Stage, We Provide:

-

Detailed 3D CAD Models

-

3D-Printed Design Concepts

-

Functional Models

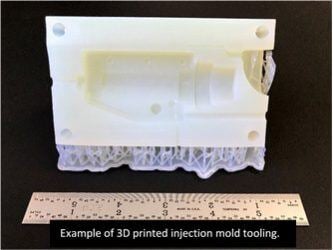

Additive Manufacturing That Accelerates Design

Our in-house additive manufacturing capabilities let us bring your ideas to life fast, with low risk and high flexibility.

Equipment highlights include:

-

Dual Head Composite 3D Printer: Continuous fiber reinforcement for parts 10x stronger than ABS.

-

Eight Carbon Filament Printers: Ideal for fixturing, prototype components, and low-volume part testing.

-

SLA Printer: High-resolution prints with smooth finishes and tight tolerances.

-

CO₂ Laser Cutter/Engraver: Enables precise cuts and custom engraving on various materials—perfect for rapid prototyping and component marking.

Advanced CAD Modeling With SolidWorks & Altium

At DEM, every design starts in SolidWorks (mechanical design) and Altium Designer (PCB design) the industry’s premier CAD platforms and a critical part of our speed-to-market advantage.

These collaborative software platforms give our team the tools to model, refine, and optimize complex architecture and design constraints with precision and efficiency. We use it to catch design flaws early, apply DFM best practices, and streamline the transition from concept to production.

No matter the complexity, our team has the tools to support rapid development and smooth handoff into manufacturing.

3D Printed Examples

3D Printed Injection Mold Tooling

3D Printed Design Concept

Go Behind the Build

Ready to Move Your Design Forward?

DEM leverages advanced rapid prototyping and additive manufacturing to accelerate product development and reduce risk.

We help you bring concepts to life fast, so you can review, refine, and validate before investing in production tooling.

From Concept to Production, All Under One Roof

Partner With a Manufacturing Team That Builds Smarter

FAQs

1. What does DEM’s product development process look like from start to finish?

Our product development process begins with concept development and requirement gathering. We then create CAD models, evaluate performance and manufacturability, and deliver validated prototypes optimized for a smooth transition to production.

2. Can product development services help reduce costs or rework later?

Yes. By applying Design for Manufacturing (DFM) principles early, DEM's product development services help you avoid costly redesigns, minimize tooling issues, and streamline production, saving both time and money.

3. I need help planning my product roadmap. Can you assist with strategy?

Absolutely. We collaborate on your product development strategy from the start, aligning your design with performance targets, regulatory requirements, and long-term scalability. The DEM team will help you make smarter early-stage decisions that pay off later.

4. Do you offer product development consulting for first-time product launches?

Yes. Our product development consulting is ideal for startups or OEMs navigating complex builds. Whether you're working with rugged electronics or regulated medical devices, we offer expert guidance to take your concept from idea to reality.