3D Printing & Prototyping

Fast, Flexible Solutions

DEM’s advanced 3D printing capabilities bring product concepts to life quickly and efficiently. Using stereolithography (SLA) and fused deposition modeling (FDM), our in-house team produces components for a wide range of applications. With flexibility and speed, we deliver high-performance parts that meet demanding project requirements.

-

Complex designs with intricate details

-

Smooth production of single parts or larger runs

-

Durable parts built to withstand tough conditions

Innovating Manufacturing With 3D Printing

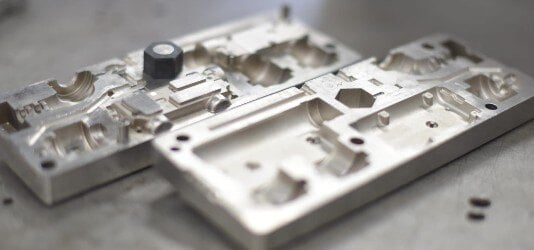

3D printing is core to our operations. We use it to manufacture functional and non-functional components, tooling molds, and even complete production-scale products. This technology enables small production runs with production-level quality, reducing time and costs while maintaining precision. By integrating 3D printing into our manufacturing process, we deliver innovative solutions that set us apart.

What Sets DEM’s 3D Printing & Prototyping Apart?

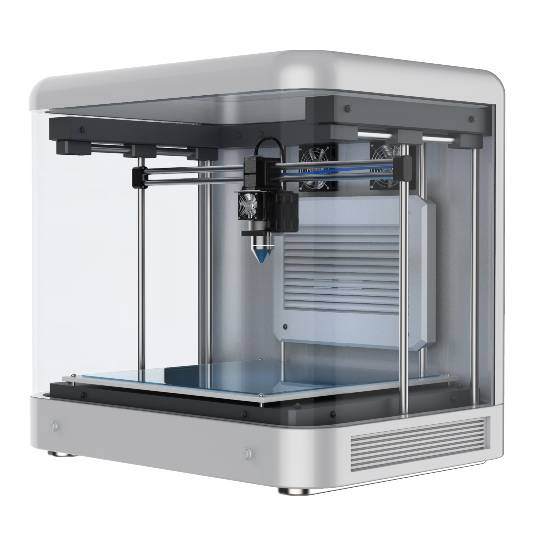

High-Volume Production

With 10 3D printers on site, we can handle larger production volumes without sacrificing speed or quality.

Wide Material Selection

We offer a broad range of materials, including fiberglass-reinforced, carbon fiber-reinforced, fire-retardant, and translucent materials.

Fast Iterations

Our rapid prototyping process allows you to quickly refine and test product concepts, helping you move from idea to production faster.

Versatile 3D Printing Solutions for Every Project

We offer both SLA and FDM 3D printing technologies to meet your specific needs. Our range of 3D printing capabilities ensures we can deliver the best solution for your project, regardless of complexity or volume.

Stereolithography (SLA)

-

High-precision prints with smooth finishes

-

Fast turnaround times

-

Handles tight tolerances and complex geometries

-

Wide range of resin options, including translucent and specialty materials

Fused Deposition Modeling

-

Versatile materials, including carbon fiber-reinforced and fire-retardant options

-

Capable of printing large or multiple parts in one run

-

Strong, durable prototypes and end-use parts

-

Cost-effective production of large or multiple components

Start Prototyping Your Idea

FAQs

1. How can 3D printing prototyping accelerate my product development?

Our in-house 3D printing prototyping capabilities let you quickly test and refine concepts before investing in production tooling. We help reduce lead times and design risk by enabling early feedback on fit, form, and function.

2. What materials are available for 3D printed prototypes?

DEM offers a range of engineering-grade materials, including fiberglass-reinforced, carbon fiber, flame-retardant, and translucent options that are ideal for both functional models and high-resolution 3D printing prototyping.

3. Can DEM support higher-volume runs with 3D printed parts?

Yes. While many firms focus only on single prototypes, DEM has the capacity to handle short-run 3D printing production using our fleet of SLA and carbon filament printers. Typically, pilot builds, field testing, or bridge manufacturing find this most useful.