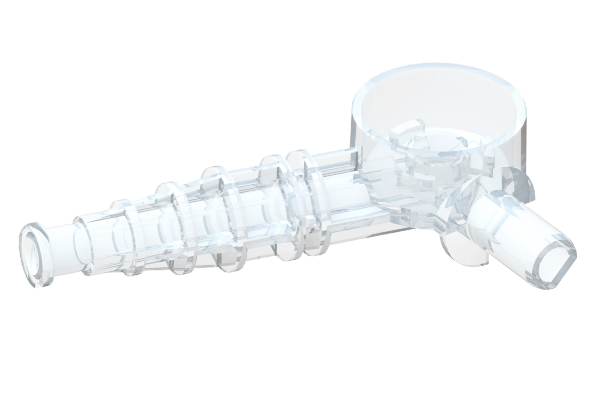

Injection Molded Components

Custom Plastic Components for Every Need

We produce high-quality injection molded plastic components to meet the most demanding specifications. Our in-house engineering team and advanced molding technology allow us to handle jobs of any size, from small runs to large-scale production.

-

Nine injection molding machines

-

Tooling options ranging from simple two-part molds to complex multi-cavity designs

-

Stock of recycled and virgin resins to match project requirements

Higher Quality Components Delivered on Time

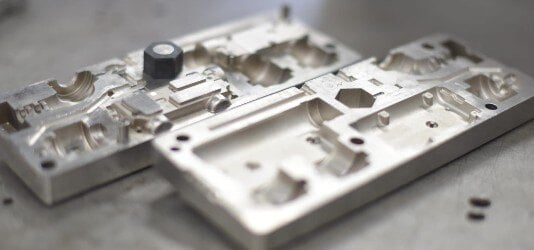

Injection molding is a core part of DEM’s manufacturing process. By managing tooling design, maintenance, and modifications entirely in-house, we ensure consistent quality, durability, and on-time delivery. With no need for outsourcing, we deliver components quickly and cost-effectively, tailored to your exact specifications.

What Sets DEM’s Injection Molded

Plastic Components Apart?

In-House Engineering

Our engineers ensure minimal downtime and on-time delivery.

Flexible Fulfillment

Choose one-time delivery or scheduled stocking for ongoing production needs.

Variety of Options

Tooling and molding capabilities that support any volume, size, or complexity.

Injection Molded Component Materials

Our broad range of resins allows for materials tailored to your project’s performance requirements. This ensures components meet various technical requirements, from strength and durability to specialized functions like conductivity.

We Stock a Variety of Recycled and Virgin Resins, Including:

-

ABS

-

Acrylics

-

Glass-filled nylons

-

Metal-filled ABS (conductive resin)

-

Nylons

-

Polycarbonates

-

Polypropylenes

-

PVC

-

Santoprene

-

Others available on a project-by-project basis

Solve Your Injection Molding Challenges

FAQs

1. What types of injection molded plastic components do you manufacture?

DEM manufactures durable, high-performance injection molded plastic components designed for defense, medical, and industrial use. Our in-house capabilities allow for precise, repeatable production of both standalone parts and overmolded electronics.

2. How do you optimize injection mold components for quality and speed?

We design and build injection mold components with scalable tooling that balances investment and annual volume. DEM’s experienced engineers create modular tools and use rapid prototyping to accelerate time to market without compromising performance.