Printed Circuit Board Assemblies (PCBAs)

Custom PCBA Solutions Built for Performance and Precision

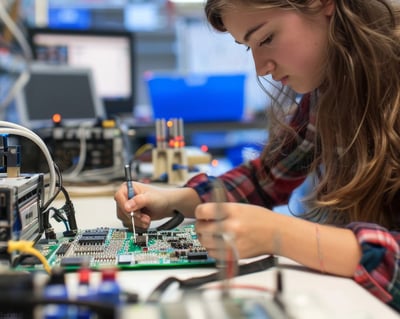

We specialize in designing and manufacturing printed circuit board assemblies (PCBAs) as part of complete product solutions. From design to assembly, we handle everything in-house. Our expert team builds PCBA solutions with efficiency in mind, to deliver high-performance, cost-effective solutions.

-

In-house PCBA manufacturing for total quality control

-

Designs optimized for performance and cost using Design for Manufacturing (DFM) methodologies

-

Advanced circuitry integration for enhanced functionality

-

Quick-turn boards for prototyping, evaluation, and validation

Rely On a Team That Goes Beyond Assembly

Our PCBA team designs boards to fit your specific requirements, from compact and lightweight to rugged and feature-rich designs. With expertise in firmware and software integration, we deliver complete solutions for even the most complex products.

What Makes DEM a Trusted Partner for PCBAs?

Precision & Quality

Our PCBAs are manufactured in a class 100 cleanroom, maintaining the highest standards of precision and cleanliness.

Advanced Integration

Our engineers can design circuitry that integrates seamlessly with external hardware, like smartphones or protective masks, to meet your specific needs.

Fast Turnaround

We’re equipped to meet tight deadlines while maintaining the highest standards of quality.

PCB Design & Innovation

Our PCBs are designed to be robust and dependable even when exposed to EMI, RF, and other environmental factors—often the most critical factors in product development.

By controlling every aspect of the design process, we ensure your PCBs exceed your requirements. Our development process incorporates DFM methodologies to ensure they can be built efficiently and fit properly in your product.

What You Can Expect

-

Scalable production capabilities

-

Expertise in designing PCBs for challenging environments

-

Stringent testing and validation at every stage of the manufacturing process

Solutions for Complex Designs & Unique Requirements

FAQs

1. What types of printed circuit board assemblies does DEM specialize in?

DEM designs and produces custom printed circuit board assemblies (PCBAs) for defense, medical, and industrial electronics. Our in-house team ensures every board meets performance, durability, and compliance requirements for critical applications.

2. How do you ensure quality in printed circuit board assembly?

Every printed circuit board assembly undergoes rigorous in-line and final testing. DEM's IPC-certified technicians use Design for Manufacturing (DFM) methods to enhance reliability, streamline builds, and ensure seamless integration into your product.

3. Why choose DEM over other printed circuit board manufacturers?

Unlike many printed circuit board manufacturers, DEM keeps all PCB assembly in-house, providing faster turnaround, tighter quality control, and 100% U.S.-based production that meets ISO 9001, ISO 13485, and ITAR standards.

4. What are DEM’s PCB assembly capabilities?

From rapid prototyping to high volume production, DEM’s PCB assembly capabilities are a key component to the value we bring to our customers. With the ability to accurately place components down to 01005 with lead pitch as fine as 0.3mm and board dimensions up to 350mmx1250mm, we’re able to take on and successfully deliver even the most challenging projects.