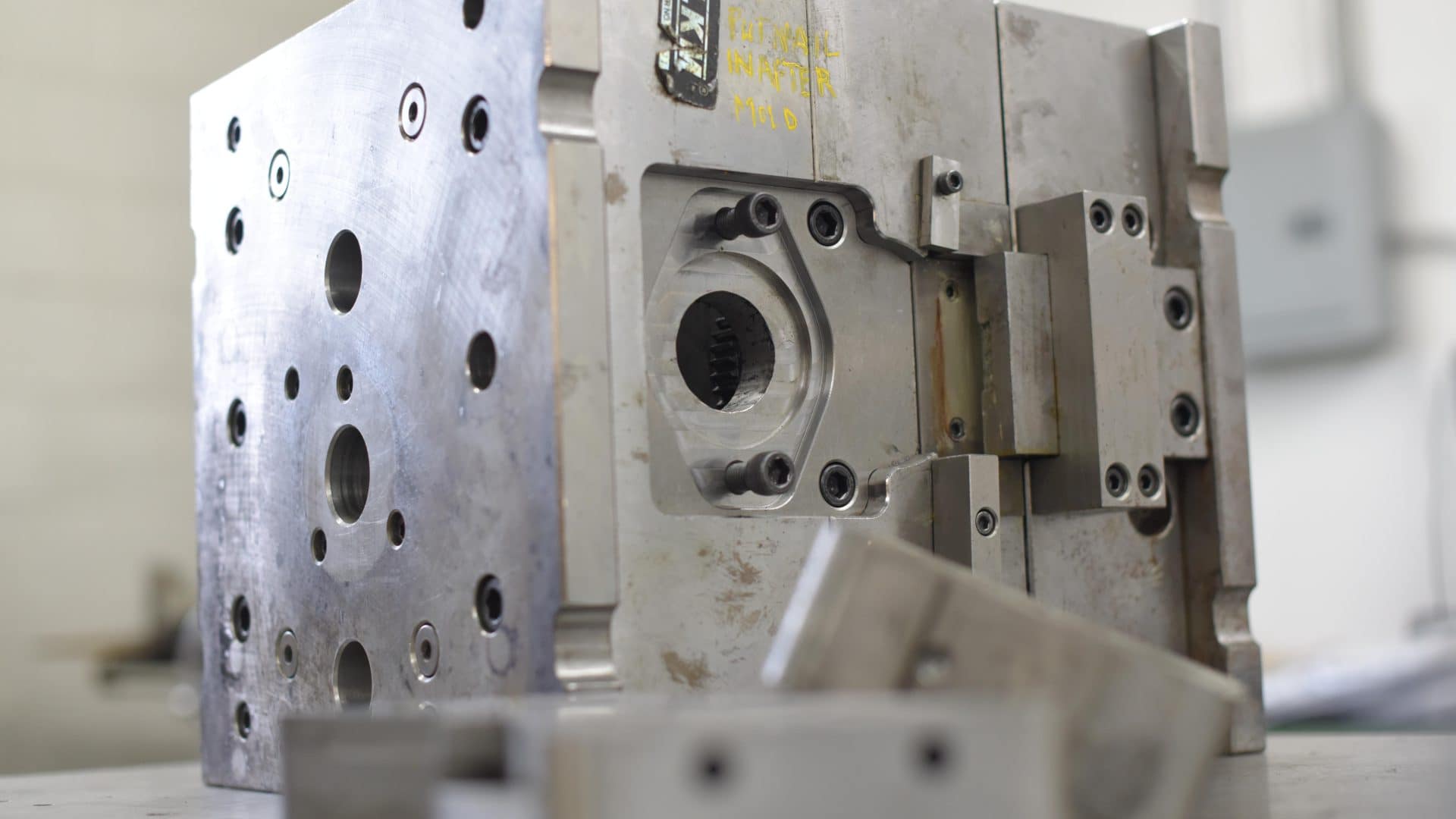

Tooling Design & Fabrication

Custom Injection Mold Tooling & Fabrication for Your Production Needs

DEM Manufacturing delivers precision injection mold tooling and fabrication tailored to your project requirements. Our in-house capabilities provide fast, flexible solutions for both low- and high-volume production.

- Advanced prototyping techniques, including aluminum molds and 3D-printed mold cavities, enable precision and efficiency for prototyping, short-run manufacturing, and producing realistic parts for full production.

- High-quality, custom stainless steel tooling solutions are engineered for exceptional durability and longevity. Built to maintain consistent quality over extended use, this tooling minimizes the need for frequent replacements and helps reduce long-term costs.

A Partnership for Long-Term Success

Our process minimizes upfront costs and focuses on designing products to meet your exact requirements. We streamline the path to production, often achieving results in as little as 10 weeks, ensuring you get to market faster and with confidence.

-

In-house tool design for full quality and timeline control

-

Configurable tooling for multiple product variations

-

Cost-efficient options for prototypes and short runs

Expertise in Tooling Design & Fabrication for Superior Production

Flexible Design

Scalable tooling supports both prototypes and full-scale production runs.

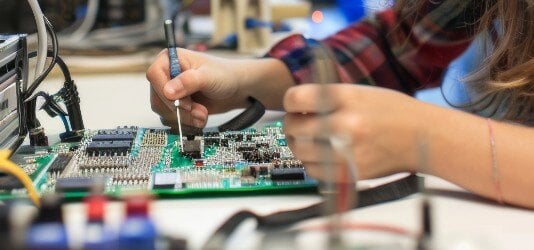

Expert Engineering

Optimized molding processes reduce cycle times while maintaining quality.

Multiple Tooling Options

Choose from stainless steel molds for high-volume production or aluminum and 3D-printed molds for prototypes and short runs.

Precision Tooling for Every Project

Our expertise in injection molding tool design and fabrication enables us to optimize production processes while maintaining flexibility. With the ability to design for bookcase, large-frame, and overmold tools, DEM can handle any project size or complexity.

What You Can Expect

-

Tooling solutions built to last

-

Concept to full-scale production in 10 weeks or less

-

A variety of options that suit your needs and budget

Superior Tooling Solutions for Your Production Goals

FAQs

1. What makes DEM’s injection mold fabrication process different?

DEM’s injection mold fabrication process is entirely U.S.-based and optimized for speed, precision, and scalability. We design and build tooling in-house to reduce lead times and ensure alignment with your production goals from day one.

2. How does DEM support flexible injection mold tooling needs?

We develop modular, configurable injection mold tooling that accommodates multiple product variants within a single mold. This approach shortens cycle times and reduces costs, especially for low-to-mid volume programs that still demand performance.