Why U.S. Military Contractors Need a Manufacturing Partner Who Can Move Fast

In today’s defense industry, speed is just as critical as quality. Military contractors are facing increasing pressure to develop, test, and deploy new technologies faster than ever before. With emerging threats, evolving battlefield requirements, and rapidly advancing technology, the ability to move quickly is a necessity.

Traditionally, manufacturing in the defense sector has been a slow and methodical process, often burdened by long lead times and outdated production methods. But in a world where new startups are disrupting the industry and foreign adversaries are advancing their own technologies at faster speeds, the slow approach is no longer viable.

U.S. defense contractors need manufacturing partners who can keep up with the pace of innovation—partners who can deliver turnkey, high-reliability solutions in weeks, not years.

In this blog, we’ll explore why speed matters more than ever for military contractors and how partnering with a responsive, highly specialized manufacturer can make all the difference in performance, cost-effectiveness, and operational success.

Military Manufacturing Is More Competitive Than Ever

The defense industry is evolving rapidly. Once dominated by a handful of large, established contractors, the landscape is now shifting as new startups and technology-driven companies enter the space. These newcomers bring cutting-edge innovations, agile development processes, and a willingness to disrupt the status quo.

The name of the game is speed and efficiency. Defense contractors who can design, prototype, and manufacture mission-critical components faster will secure more contracts and gain a competitive edge in an industry where timelines can mean the difference between operational success and failure.

However, speed alone isn’t enough—military applications demand uncompromising reliability. Defense equipment must withstand extreme conditions, function flawlessly in mission-critical environments, and meet stringent compliance standards, including ITAR, MIL-SPEC, and environmental testing protocols like MIL-STD-810.

Balancing rapid development with rugged reliability is a challenge that many military manufacturers struggle to overcome. That’s why choosing the right full-service manufacturing partner—one that can move fast while maintaining precision and compliance—is critical.

How the Right Full-Service Manufacturing Partner Speeds Up Product Development Timelines

At DEM Manufacturing, we understand that defense contractors can no longer afford long development cycles. That’s why we’ve designed a fast-turn, high-reliability manufacturing process that gets mission-critical products into the field as quickly as possible—without sacrificing quality or compliance.

Turnkey Development: From Concept to Full-Scale Production in as Little as 10 Weeks

Traditional full-service product design and manufacturing partners often require 12–18 months to take a product from concept to production. This creates bottlenecks that increase costs, delay revenue, and allow competitors to steal business away from you.

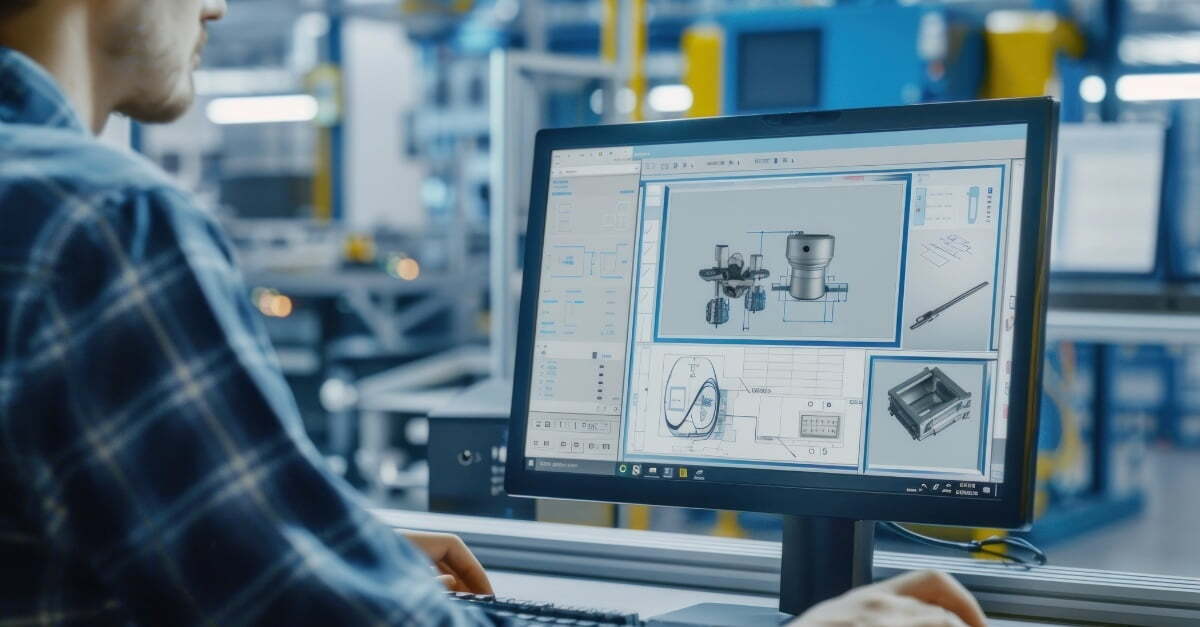

At DEM, we cut that time down to as little as 10 weeks. Our vertically integrated, U.S.-based manufacturing model means that everything from design and prototyping to full-scale production happens under one roof. No unnecessary delays, no outsourcing risks—just a streamlined process built for speed and precision.

DFM Optimization: Reducing Rework and Inefficiencies from the Start

Speed alone isn’t enough—you also need a product that’s built for efficient, cost-effective production. That’s why we apply Design for Manufacturability (DFM) best practices from the very beginning.

By identifying and eliminating potential production issues early, we ensure that every product is optimized for both performance and scalability before we ever begin full-scale manufacturing. This leads to fewer redesigns, streamlined assembly, and lower costs overall.

Advanced Prototyping & Testing

Waiting months for a prototype can be a major bottleneck in military product development. DEM Manufacturing accelerates this process with advanced prototyping and in-house validation.

We utilize:

- 3D Modeling & Additive Manufacturing – Rapidly produce functional prototypes for real-world testing.

- In-House Performance Testing – Ensuring every prototype meets military-grade durability and compliance standards before full production.

Because we control the entire prototyping and validation process in-house, we can cut testing and iteration timelines dramatically—getting you a finalized, production-ready design faster than traditional manufacturers.

Custom, Low-MOQ Production

One of the biggest challenges defense contractors face is balancing development flexibility with production scalability. Many manufacturers require high minimum order quantities (MOQs), forcing you to commit to large runs before fully validating a product.

We eliminate that problem by offering custom, low-MOQ production options, allowing you to reduce upfront costs, make faster design changes, and scale production when you’re ready.

This agile manufacturing model is essential for military applications, where adaptability and precision are key. Instead of being locked into high-cost, inflexible production contracts, you get the flexibility to develop, test, and scale on your own terms.

Speed and Efficiency Without Compromising Cost-Effectiveness

DEM Manufacturing’s process is not just about getting a product into the field quickly—it’s also about maximizing cost-efficiency and profitability. The longer it takes to bring a defense product to market, the higher the development costs and the greater the risk of losing contracts to competitors. A manufacturing process that delivers faster, reduces waste and eliminates inefficiencies is one that directly improves your bottom line.

Partner with an ITAR-Certified, U.S.-Based Manufacturer You Can Trust

When it comes to manufacturing in the defense sector, there’s no room for delays, inefficiencies, or non-compliance. By working with a fast-turn, full-service manufacturer like DEM Manufacturing, you can secure contracts faster, speed up operational readiness, and generate revenue sooner. Plus, with ITAR-registered, 100% U.S.-based production, we minimize offshore supply chain risks and unpredictable lead times.

Our capabilities include:

- Analog & Digital Communication Devices

- Custom Cabling & Connectors

- Printed Circuit Board Assemblies (PCBAs)

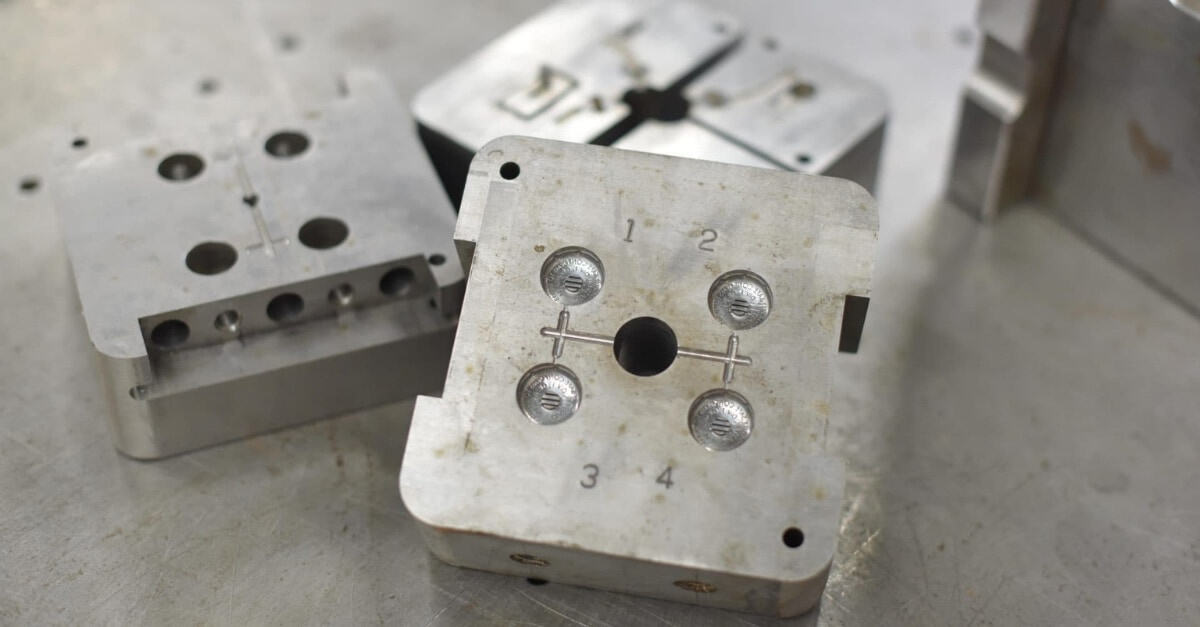

- Tooling Design & Fabrication

And much more.

Our cost-effective, precision-engineered solutions ensure you get mission-critical products quickly—without sacrificing quality, durability, or reliability. If you’re looking for a manufacturing partner that understands the urgency of military applications, let’s talk. Schedule a call with our team today to see how we can help you bring your mission-critical products to market.

Craig Padula

Craig Padula is the president of DEM Manufacturing, a fully integrated U.S.-based OEM specializing in the product development and manufacturing of a wide range of electronic and mechanical devices. DEM is constantly adding new innovative products to its portfolio in the areas of defense, aerospace, and medical. He leads DEM’s focus on growth, capability expansion, and new talent, helping customers reduce risk and get products to market faster. Craig holds a B.S. in Mechanical Engineering from the University of Dayton and resides in Auburn Township, Ohio, with his wife, Hollie, and two children, Nico and Rocco.

By

By

.jpg)