Our Solutions

Full-Service Product Development & Manufacturing

DEM combines design, engineering, and manufacturing into a seamless process that transforms ideas into high-performance electronic devices. From initial concepts to full-scale production, our Design for Manufacturing (DFM) process ensures precision, efficiency, and manufacturability. Leveraging advanced tools, collaborative expertise, and thorough testing, we deliver innovative solutions optimized for cost, quality, and scalability.

Design

From 3D modeling to rapid prototyping, we turn concepts into manufacturable products with speed and precision, grounded in design for manufacturability principles that help reduce surprises later in the build.

Engineer

Mechanical and electrical design, thorough testing, and precise documentation ensure optimal functionality, performance, and manufacturing design alignment throughout the development process.

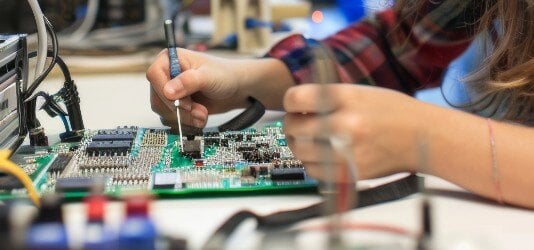

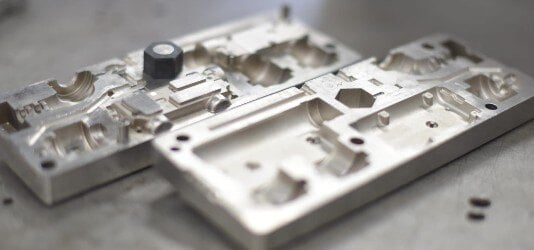

Manufacture

Our four-stage process delivers durable, precision-engineered products built to exceed expectations.

Capabilities That Deliver Turnkey Electronics Manufacturing Solutions

Partner With a Manufacturer You Can Count On

FAQs

1. Why is design for manufacturability important in product development?

Design for manufacturability improves production speed, lowers costs, and ensures consistent quality. At DEM, we integrate this principle throughout engineering to streamline your path from concept to production.

2. How do you ensure high-performance results through manufacturing design?

DEM’s manufacturing design services prioritize durability, cost-efficiency, and performance. Every product undergoes design validation, performance testing, and tool planning to ensure reliable output from day one.

3. What industries benefit most from DEM’s design for manufacturing expertise?

Our design for manufacturing capabilities support defense, medical, industrial, and communications sectors. DEM’s 100% U.S.-based production and rigorous design process meet the demands of complex, high-stakes applications.