Medical Device Product

Development & Manufacturing

Virtec Medical & Virtec Enterprises Are Now DEM Medical!

Bring Your Medical Device Ideas to Life

DEM Medical supports medical device manufacturing from concept to production, meeting your specifications and strict industry standards. Our services cover everything from rapid medical device prototyping to full-scale manufacturing, providing comprehensive solutions at every stage of your project.

-

FDA registered for Class I and II medical devices

-

ISO 9001 and 13485 certified Quality Management Systems (QMS)

-

FDA 510(k) support

Shorten the Time Between Concept & Production

Our streamlined process moves your product efficiently from concept to prototype and into production. And our scalable solutions provide the support you need, regardless of project size.

- We start by understanding your product, goals, and challenges to ensure we’re the right partner.

- Then, we collaborate to create a detailed project requirements plan, defining scope and performance standards.

- Next, we deliver a clear proposal with milestones for every deliverable, ensuring predictable timeliness for your medical device development.

DEM Medical’s Advantage in Medical Device Manufacturing

Product Development

As an FDA-registered manufacturer, we ensure every product meets regulatory requirements across medical device engineering, prototyping, and production.

Scalable Manufacturing

Our processes are tailored to your specific production needs, from prototyping to medium-volume runs.

High Quality Standards

Our robust QMS delivers consistent results, ensuring each device meets the reliability and performance expectations of modern medical device product development.

A Proven Process for Medical Device Development

At DEM Medical, we follow a rigorous development process that benefits customers by streamlining production, reducing risks, and ensuring that products meet both regulatory and market demands.Step 1: Concept Creation & Benchmarking

We create a clean sheet design or optimize your initial concepts. Every product we develop is designed and manufactured to fulfill our customers’ performance objectives and to meet stringent FDA regulatory requirements.

Step 2: Prototyping

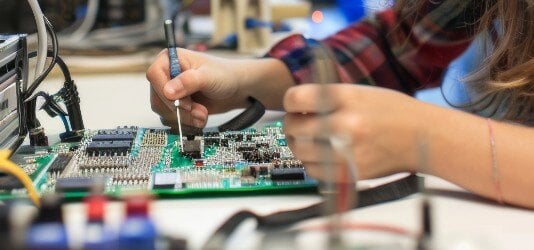

Rapid medical device prototyping and initial confidence testing are completed. We then perform any necessary design iterations to ensure the product functions as intended before it is subjected to full validation testing.

Step 3: Product Validation

DEM Medical provides you with production-intent samples in quantities needed to complete the validation testing. We can also work directly with outside testing facilities to coordinate the validation work.

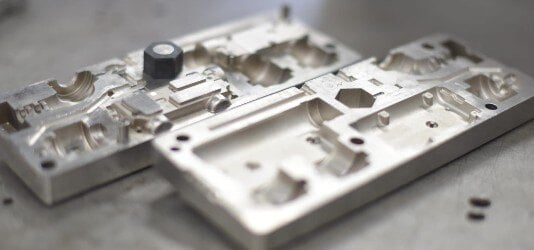

Step 4: Conversion to High-Volume Production

We build and debug high-volume tooling, develop assembly processes, and create robust quality control plans. Once regular production is underway, we provide high-quality products by constantly monitoring important product features through our QMS systems.

Experience in Class I and II Medical Device Applications

Our engineering solutions have contributed to many successful medical projects and products.Previous Product Applications Include:

-

Homecare dialysis and monitoring

-

Heated humidifiers

-

Surgical tables

-

Suction devices

-

Laparoscopic surgical devices

-

Catheters

-

Ventilatory devices

-

Laser therapy

Take Your Medical Device From Concept to Market

FAQs

1. How do you support full-cycle medical device development?

From early concept refinement and prototyping to final regulatory-ready manufacturing, DEM is your partner in end-to-end medical device development. Our ISO 13485-certified processes are built to help you bring compliant devices to market faster and with less risk.

2. What makes a reliable medical device manufacturing partner?

DEM's vertically integrated team handles everything in-house, from medical device engineering to tooling and production. This U.S.-based model ensures speed, compliance, and transparency that offshore vendors can’t match.

3. Can DEM help prototype and test medical device concepts before production?

Yes. We provide rapid medical device prototyping using additive manufacturing, precision machining, and in-house PCB assembly. This accelerates validation and helps you iterate designs before investing in full-scale production.

4. Can you help navigate FDA requirements for my medical device?

Yes. DEM is ISO 13485 certified and FDA-registered, and we frequently assist clients with documentation and design practices that align with regulatory standards. While we don’t provide legal or submission services, our process is built to support FDA-compliant medical device product development.

5. What’s the minimum volume you can support for a new medical device?

We offer flexible order volumes and can support early-stage medical device manufacturing with low-volume production. This is ideal for startups or pilot programs looking to scale after clinical validation or initial launch.