The Advantages of a U.S.-Based, ITAR-Compliant Supply Chain

With increased trade tensions and global supply chain disruptions, offshore production, once viewed as an effective cost-saver, is more likely to introduce delays, compliance headaches, and security concerns that outweigh perceived benefits.

For companies in the defense sector, quality, compliance, and control are non-negotiable. An unreliable supply chain can lead to delayed contracts, regulatory violations, and even compromised national security.

In this post, we’ll break down the hidden costs of overseas sourcing, explore the critical advantages of a U.S.-based, ITAR-compliant manufacturing partner. We’ll also show how DEM Manufacturing helps defense contractors streamline development, protect sensitive technologies, and get to market faster with full confidence in every step of the process.

The Hidden Risks of Offshore Production

Offshoring might seem like the economical choice on paper, but it can also be a gamble that comes with serious consequences for businesses.

With U.S. tariff policies in constant flux and certain imports subject to steep rates, companies that rely on overseas sourcing must also navigate challenges such as:

- Longer lead times due to customs delays and extended shipping routes

- Communication breakdowns across time zones and language barriers

- Higher risk of IP theft in countries with lax enforcement

- Limited control over quality and process compliance

For the defense industry, these challenges pose unacceptable risks. Mission-critical products demand flawless compliance and on-time delivery. With complex approvals, strict security protocols, and uncompromising deadlines, defense contractors need absolute dependability in their supply chain.

That dependability begins with U.S.-based production.

What ITAR Compliance Actually Means

When it comes to handling sensitive technologies, International Traffic in Arms Regulations (ITAR) compliance is one of the most critical standards.

Managed by the U.S. Department of State, ITAR governs the manufacture, export, and handling of defense-related articles and services listed on the U.S. Munitions List (USML). Any product, design, or data that falls under ITAR must be developed and managed within strict guidelines to prevent unauthorized access or distribution:

- Only ITAR-registered companies are legally allowed to work on defense-related projects.

- Government contractors, OEMs, and suppliers are required to source from compliant manufacturers to maintain their own regulatory standing.

ITAR compliance ensures that sensitive defense technologies stay in the U.S., protected from foreign interference or misuse.

Working with an ITAR-compliant manufacturer like DEM gives you peace of mind that your project is being handled securely, with full traceability and documentation at every stage. It also simplifies procurement and speeds up approval cycles, because you’re working with a partner who understands and meets defense-grade requirements from day one.

Why U.S.-Based, Vertically Integrated Manufacturing Is Superior

When your project is mission-critical, every step needs to be controlled, compliant, and fast. That’s exactly what DEM delivers. As a U.S.-based, vertically integrated, ITAR-registered manufacturer, we provide end-to-end solutions that eliminate guesswork and reduce risk.

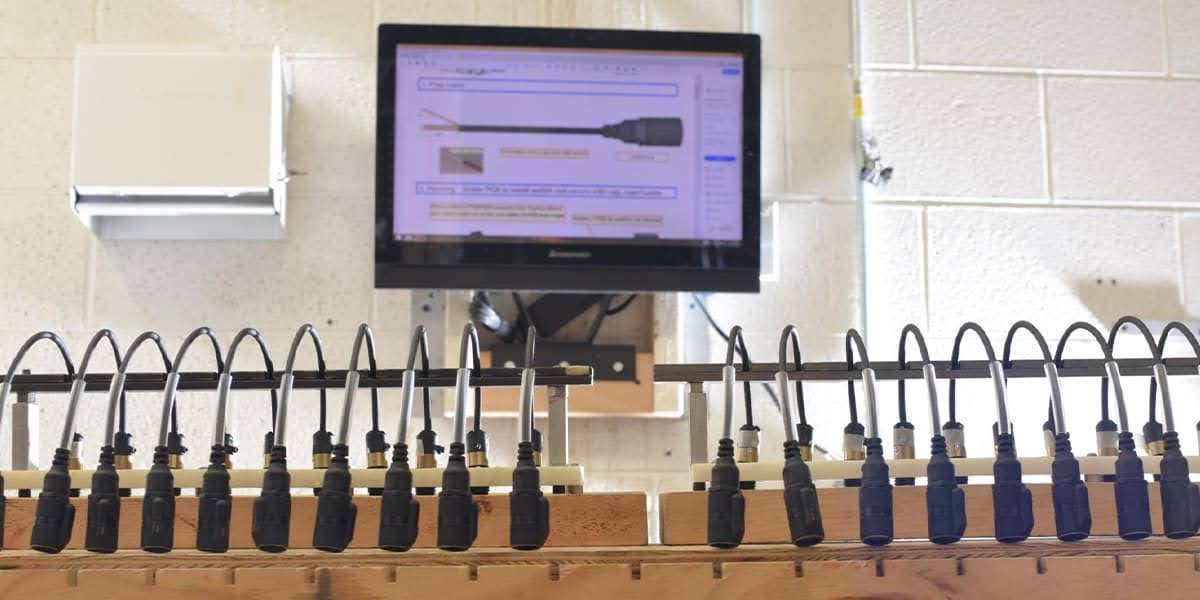

At DEM, we specialize in designing and manufacturing molded plastic components and small electronic components for high-performance defense and industrial applications. From PCB layout and circuit design to custom connector builds and full-scale production, every part of our process happens on U.S. soil with design, engineering, and manufacturing teams working side by side.

This structure allows us to move faster, operate more securely, and stay aligned with strict compliance requirements throughout every project.

Faster Iteration Through In-House Collaboration

Our vertically integrated model means your design doesn’t get handed off to disconnected vendors or offshore partners. Instead, DEM’s engineers, quality experts, and production leads work together in real time to:

- Shorten development cycles

- Troubleshoot and optimize designs faster

- Ensure design-for-manufacturing (DFM) is applied from day one

This level of collaboration reduces lead times, minimizes rework, and avoids late-stage surprises, ultimately getting your product to market faster.

Built to Withstand Global Disruptions

By keeping production in the U.S., DEM helps customers:

- Avoid unpredictable tariffs and rising shipping costs

- Bypass global supply chain bottlenecks

- Protect intellectual property with strict U.S. enforcement standards

- Maintain clear communication across time zones and teams

You get more transparency, faster turnarounds, and fewer surprises, all while maintaining full ITAR compliance.

Ready to Scale When You Are

At DEM, we’re able to help you scale quickly and confidently. Because we manage everything in-house, we can ramp up production without relying on third-party capacity.

Whether you're building low volumes for initial deployment or preparing for larger-scale defense contracts, our team can flex with your needs while maintaining quality and compliance.

Talk to a DEM Expert Today

If your supply chain exposes you to tariffs, delays, or compliance risks, it’s time for a strategic shift.

DEM Manufacturing provides defense contractors and OEMs with a 100% U.S.-based, ITAR-compliant manufacturing solution. Our vertically integrated structure accelerates production, protects sensitive data, and delivers rugged, high-performance products.

Whether launching a new program or transitioning an existing one, our experts are ready to help.

What to expect with DEM:

- Full ITAR compliance

- Defense-grade manufacturing experience

- Prototype-to-production in as little as 10 weeks

- U.S.-based design, engineering, and manufacturing under one roof

Talk to a DEM expert today to build a more secure, responsive supply chain.

Craig Padula

Craig Padula is the president of DEM Manufacturing, a fully integrated U.S.-based OEM specializing in the product development and manufacturing of a wide range of electronic and mechanical devices. DEM is constantly adding new innovative products to its portfolio in the areas of defense, aerospace, and medical. He leads DEM’s focus on growth, capability expansion, and new talent, helping customers reduce risk and get products to market faster. Craig holds a B.S. in Mechanical Engineering from the University of Dayton and resides in Auburn Township, Ohio, with his wife, Hollie, and two children, Nico and Rocco.

By

By

.jpg)